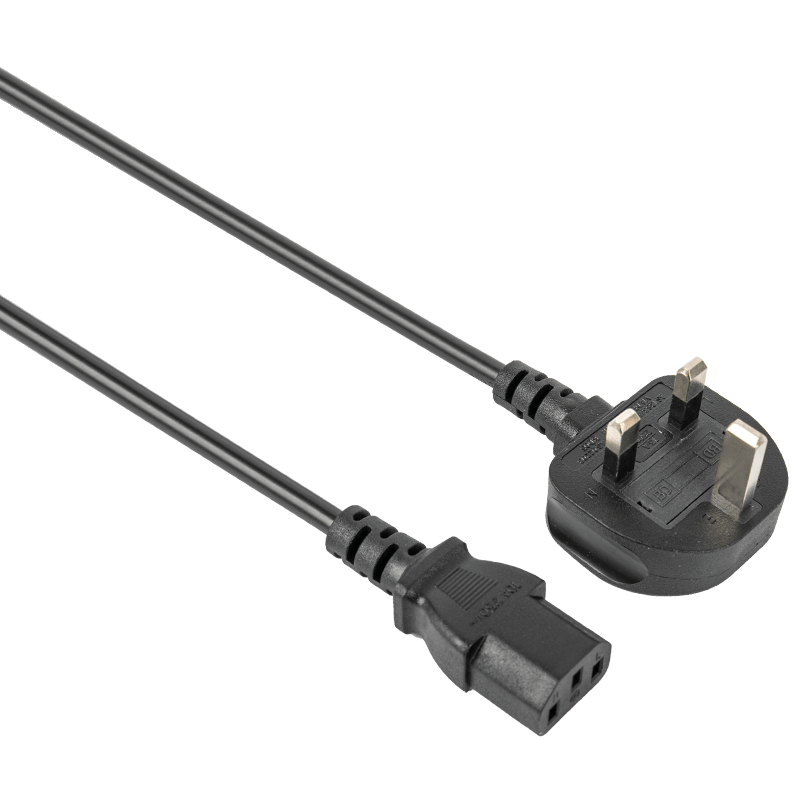

Heavy-duty AC power connectors play a critical role in ensuring reliable power distribution in industrial settings by employing a combination of design features and materials that enhance their performance and reliability. Here are ways in which these connectors achieve reliable power distribution:

High Current Ratings: Heavy-duty AC power connectors are designed to handle high electrical currents. They are rated for specific current capacities, which ensures that power-hungry machinery and equipment receive the necessary electricity without overloading the connectors. This prevents overheating and electrical failures, ensuring a consistent power supply.

Robust Construction: These connectors are built with durable materials, such as metal or high-quality thermoplastics, which are chosen for their resistance to wear and tear. The robust construction helps these connectors withstand the physical stresses and mechanical impacts common in industrial environments.

Secure and Reliable Connections: Heavy-duty connectors often feature secure locking mechanisms that keep connections firmly in place. This is crucial in environments with vibration, movement, or potential cable tugging. A secure connection prevents accidental disconnections and maintains power continuity.

Modularity: Many heavy-duty connectors are modular, allowing users to customize the number and type of connections as needed. This modularity simplifies installation, maintenance, and changes to the power distribution system, providing flexibility in adapting to evolving industrial requirements.

Corrosion Resistance: In industries where exposure to chemicals or corrosive agents is common, heavy-duty connectors are often designed with special coatings or constructed from corrosion-resistant materials. This ensures that connectors remain reliable and free from degradation in challenging environments.

Temperature Tolerance: Heavy-duty connectors are engineered to withstand extreme temperature variations. They can operate effectively in both high-temperature and low-temperature environments, ensuring that power distribution remains consistent and reliable regardless of temperature fluctuations.

Safety Features: To enhance safety, heavy-duty connectors may incorporate features like touch-proof designs, polarization, and keying. These safety features prevent incorrect connections and reduce the risk of electrical accidents, ensuring a safe and reliable power distribution system.

IP (Ingress Protection) Ratings: Heavy-duty connectors are often rated with IP ratings that indicate their resistance to dust and moisture ingress. In environments where these elements are present, high IP-rated connectors provide protection against potential electrical faults due to contaminants.

Cable Strain Relief: Many heavy-duty connectors include cable strain relief mechanisms that secure and protect the cable connections. This feature helps prevent damage to the cables and maintains a stable electrical connection, even in situations where cables are subject to movement or tension.

Adherence to Standards: Heavy-duty AC power connectors are designed to meet industry standards and regulations for safety and performance. Compliance with these standards ensures that the connectors are engineered to provide reliable power distribution while minimizing the risk of electrical faults and hazards.

By incorporating these design features and using high-quality materials, heavy-duty AC power connectors ensure reliable power distribution in industrial settings. They are a crucial component of maintaining uninterrupted production processes, safeguarding equipment, and promoting worker safety in demanding and dynamic manufacturing environments.

2023.03.23

2023.03.23

2023.03.23

2023.03.23

Tel:0086-574 - 62162855

E-mail:[email protected]

Address:NO.20, Changzhen Road, Sibei Village, Simen Town, Yuyao City, Ningbo, Zhejiang, China 315472